Horizontal Plastic Pellet Mixer

Mixing capacity: upon request (Ex. 150 ~ 500 kg).

Horizontal Plastic Pellet Mixer

Mixer is for mixing PP (virgin or recycled) with masterbatch/ carbonate to have color yarn....

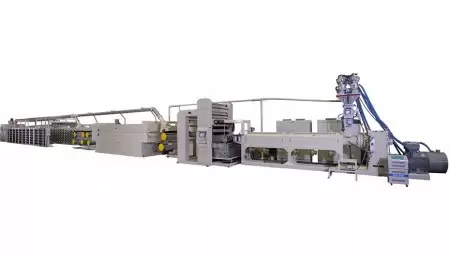

High Speed PP Flat Yarn Making Machine

The design of High Speed PP Flat Yarn Making Machine is specially for producing PP flat yarn....

Circular Loom

Circular Loom is equipped with 6 shuttles or 8 shuttles (depends on the customer’s demand)...

Flexographic Printing Machine (Roll to Roll)

Our Flexographic Printing Machine (roll to roll) has high production performance for printing...

Flexographic Printing Machine (Manual Feeding Type)

The Flexographic Printing Machine (manual feeding type) provides excellent performance for printing...

Roll to Roll Gusseting Machine

Roll to Roll Gusseting Machine is applied to make side gusset for PP woven bags. The gusset...

Automatic Bag Cutting & Sewing Machine

Automatic Bag Cutting & Sewing Machine is equipped with 90∘transfer grippers, two servo motor,...

Automatic Bag Cutting & Sewing Machine (Gusseting Type)

Auto Bag Cutting & Sewing Machine (Gusseting Type) includes Gusseting Device, Cutting Unit...

Automatic Bag Cutting Machine

Automatic Bag Heat Cutting Machine is applied for cutting PP woven bag. This machine is stable...

Lamination Machine

The lamination machine is especially for coating PP or PE on Woven Fabric, BOPP Film, Kraft...

Horizontal Plastic Pellet Mixer

Horizontal Plastic Pellet Mixer is suitable for plastic raw material, color mixing and master...

-1.jpg?v=873d0170)