PP Woven Sack Machinery

PP Woven Sack Machinery

PE / PP woven bags are traditional bags in packaging industry. The applications of PE / PP woven bags are wide variety of packing agro products, chemical products, fertilizer, flour, sugar... etc. The features are high mechanical and impact strength, resistant to abrasion and bending, have low weight, and easy to dispose of or recycle.

TON KEY has been in this industry for more than 35 years and has many clients around the world. We do like to provide information for the interested investors to make ultimate profits.

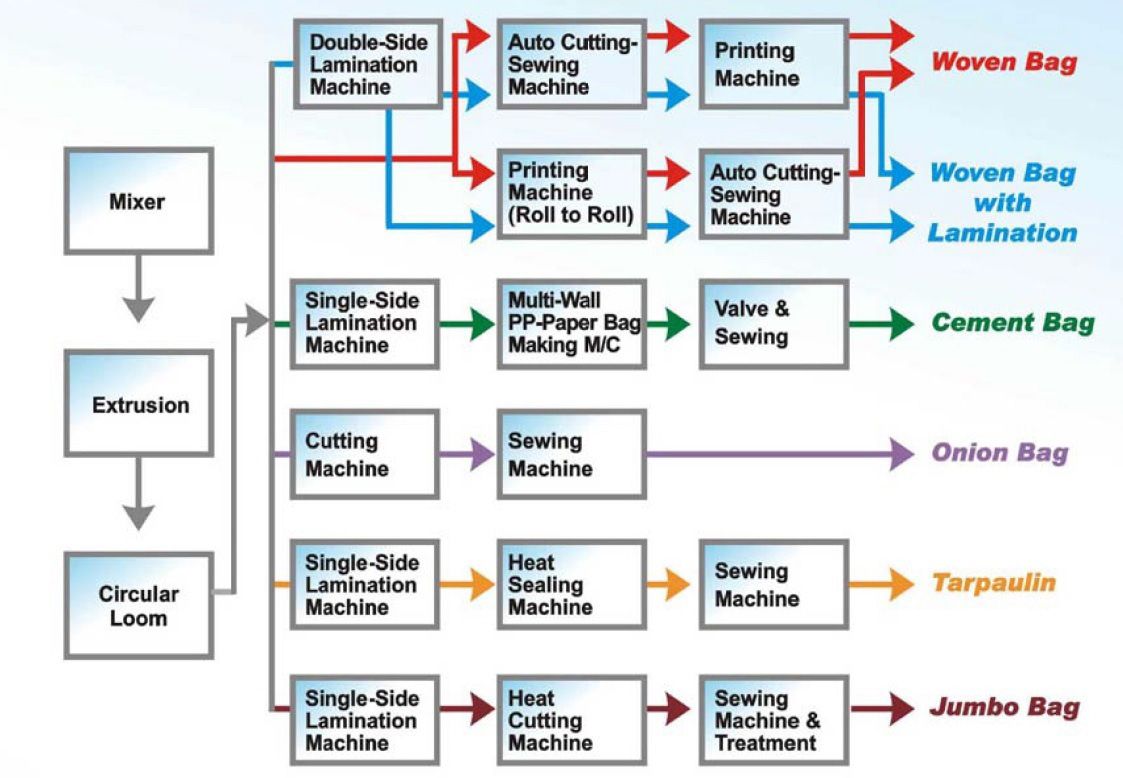

Flow Chart / PP Woven Sack Machinery

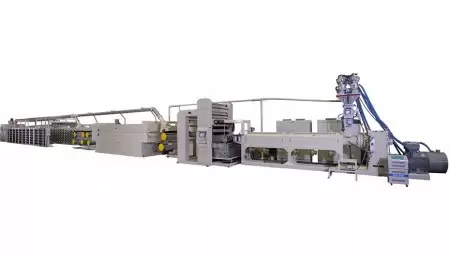

High Speed PP Flat Yarn Making Machine

TK-GE100-1000-156H (FW-350M)

The design of High Speed PP Flat Yarn Making Machine is specially for producing PP flat yarn....

DetailsCircular Loom

TK-3/900SR, TK-4/800H, TK-6/900CR, TK-6/850GB-R, TK-6/1500S, TK-8/1500SR, TK-8/2200

Circular Loom is equipped with 6 shuttles or 8 shuttles (depends on the customer’s demand)...

DetailsFlexographic Printing Machine (Roll to Roll)

TKNRP-20126C

Our Flexographic Printing Machine (roll to roll) has high production performance for printing...

DetailsFlexographic Printing Machine (Manual Feeding Type)

TKMP-4C

The Flexographic Printing Machine (manual feeding type) provides excellent performance for printing...

DetailsRoll to Roll Gusseting Machine

TKTRG-700

Roll to Roll Gusseting Machine is applied to make side gusset for PP woven bags. The gusset...

DetailsAutomatic Bag Cutting & Sewing Machine

TKCS-2012/EM/CH

Automatic Bag Cutting & Sewing Machine is equipped with 90∘transfer grippers, two servo motor,...

DetailsAutomatic Bag Cutting & Sewing Machine (Gusseting Type)

TKGS-2012/EM/CH

Auto Bag Cutting & Sewing Machine (Gusseting Type) includes Gusseting Device, Cutting Unit...

DetailsAutomatic Bag Cutting Machine

TKBC-1500

Automatic Bag Heat Cutting Machine is applied for cutting PP woven bag. This machine is stable...

DetailsLamination Machine

TK-LA95-18SD

The lamination machine is especially for coating PP or PE on Woven Fabric, BOPP Film, Kraft...

DetailsHorizontal Plastic Pellet Mixer

V-TY-6R

Horizontal Plastic Pellet Mixer is suitable for plastic raw material, color mixing and master...

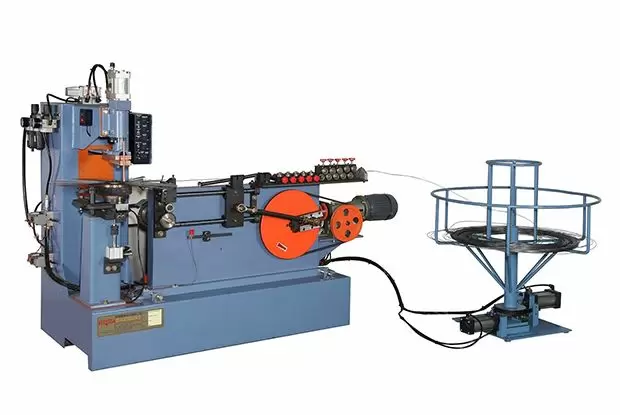

DetailsBobbin Yarn Cutter

Waste Yarn Cutter, Bobbin Yarn Cutting Machine

Instead of using manual blade or electric hot wire to clean waste yarn in the bobbins, the Bobbin...

DetailsHydraulic Baling Press

TK-BP30T

Our Hydraulic Baling Press model includes 30 tons and 60 tons. You can simply press buttons...

DetailsPP Woven Sack Machinery - PP Woven Sack Machinery | Plastic Processing Machines Manufacturer | TON KEY

Located in Taiwan since 1987, TON KEY INDUSTRIAL CO., LTD. has been a plastic processing machinery manufacturer. Their main processing machines, including PP Woven Sack Machinery, PP Woven Mat Machinery, Plastic Waste Recycling Machinery, PP / PE Monofilament Rope Machinery, PP Fiber Rope (Polytwine) Making Plant, PP Woven Sack Machinery, PE Tarpaulin Making Equipment and Fan Guard Machinery, which are sold worldwide with solid reputation.

TON KEY INDUSTRIAL CO., LTD. is a Specialist manufacturer / exporter of plastic processing machinery. Main Product: Plastic Recycling Machine, PP Rope Making Machine, PP Heavy Duty Packing Tape Making Machine, Needle Loom...etc. TON KEY's industrial plastic processing machines are built with alloy steel screw and T-Die for long-lasting efficiency and duration. They are also lightweight, water resistant, high strength and easy to operate.

TON KEY has been offering customers high-quality plastic processing machines and production lines, both with advanced technology and 30 years of experience, TON KEY ensures each customer's demands are met.

-1.jpg?v=873d0170)