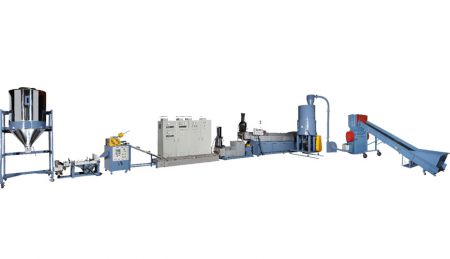

Plastic Waste Recycling Machine (Spaghetti Type with Side-feeding)

TK-85SC-S, TK-100SC-S, TK-125SC-S, TK-150SC-S, TK-175SC-S

Plastic Pelletizer, Plastic Pelletizing Machine, Plastic Granulator, Plastic Recycling Extruder

Plastic waste recycling machine (spaghetti type with side-feeding) is one of our most popular models in market. The model is especially designed for lightly waste recycling. It is good for working plastic waste such as plastic bags, PP yarn waste (laflat), PP straw waste, shrink film waste, … and so on.

Features

- Side-feeding device

- Silo device to keep crushed material

- Material feeding directly to screw working stably

We have been supplying a good number of recycling machines to many customers around the world. Mostly PP woven sack making factories use this model for their own waste. After recycling it can get good quality pellets and re-use any plastic item production.

Welcome your comment with photos of plastic waste and we can figure out suitable solution for you.

Specification

Model: TK-85SC-S, TK-100SC-S, TK-125SC-S, TK-150SC-S, TK-175SC-S

| Item No. | Model | TK-85SC-S | TK-100SC-S | TK-125SC-S | TK-150SC-S | TK-175SC-S |

| A. | Output (kg/hr.) | 100-175 kg | 150-280 kg | 200-350 kg | 300-500 kg | 500-700 kg |

| B. | Side-feeding Device | |||||

| 1. | Air Blower | 5 HP | 5 HP | 7.5 HP | 7.5 HP | 10 HP |

| 2. | Silo | 1500 L | 2000 L | 2500 L | 2500 L | 2500 L |

| 3. | Screw | 5 HP | 7.5 HP | 10 HP | 15 HP | 15 HP |

| 4. | Stirring Blade | 2 HP | 2 HP | 5 HP | 7.5 HP | 7.5 HP |

| C. | Main Extruder | |||||

| 1. | L/D | 36/1 | 36/1 | 36/1 | 36/1 | 36/1 |

| 2. | Screw Diameter | 85 mm | 100 mm | 125 mm | 150 mm | 175 mm |

| 3. | Main Motor | 60 HP | 100 HP | 125 HP | 150 HP | 200 HP |

| 4. | Heating Capacity | 40 KW | 60 KW | 80 KW | 100 KW | 120 KW |

| 5. | Hydraulic Screen Changer | 3 HP | 5 HP | 7.5 HP | 7.5 HP | 7.5 HP |

| D. | Secondary Extruder | |||||

| 1. | L/D | 8/1 | 8/1 | 8/1 | 8/1 | 8/1 |

| 2. | Main Motor | 15 HP | 30 HP | 30 HP | 40 HP | 50 HP |

| 3. | Heating Capacity | 8 KW | 10 KW | 15 KW | 15 KW | 20 KW |

| E. | Cutting Device | 3 HP | 5 HP | 7.5 HP | 10 HP | 15 HP |

| F. | Vibration Screener | 1/4 HP x 2pcs | 1/4 HP x 2pcs | 1/4 HP x 2pcs | 1/4 HP x 2pcs | 1/3 HP x 2pcs |

| G. | Air Blower | 3 HP | 5 HP | 7.5 HP | 7.5 HP | 10 HP |

| H. | Collection Tank | 800 L | 800 L | 1000 L | 1000 L | 1000 L |

- Photo Gallery

- Recycling Machine TK-125SC-S

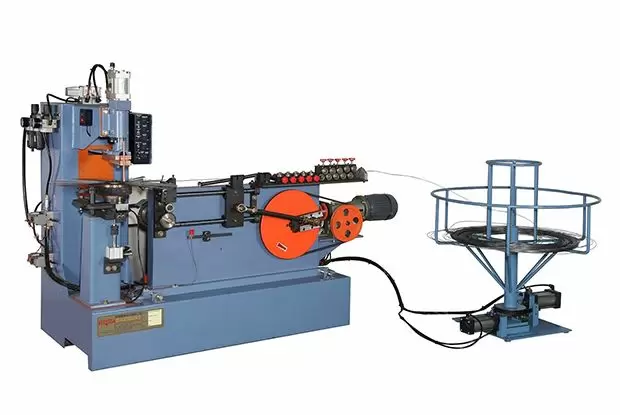

- Side-Feeding Device

- Hydraulic Screen Changer for Main Extruder (1)

- Hydraulic Screen Changer for Main Extruder (2)

- Main Extruder

- Vents

- Control Box

- Hydraulic Unit

- 1st Extruder + 2nd Extruder

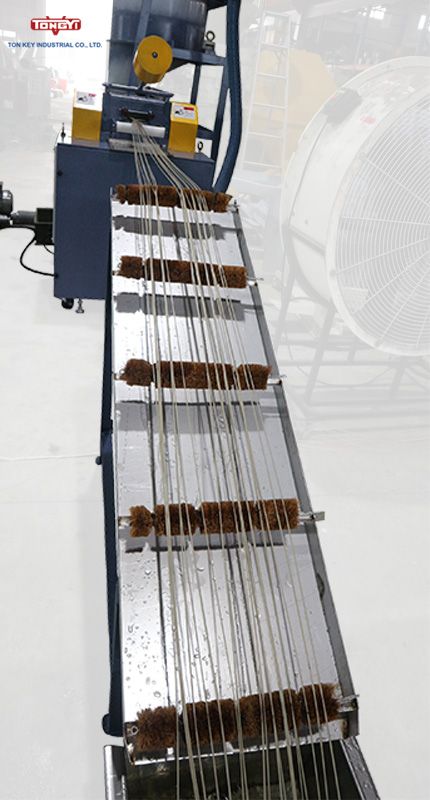

- Dewatering Stand

- Cutting Device

- Air Blower + Collection Tank

- Vibration Screener + Air Blower

- Recycling Machine TK-125SC-S

- Movies

- Files Download

Plastic Waste Recycling Machine (Spaghetti Type with Side-feeding) - Plastic Waste Recycling Machine (Side-feeding) | Plastic Processing Machines Manufacturer | TON KEY

Located in Taiwan since 1987, TON KEY INDUSTRIAL CO., LTD. has been a plastic processing machinery manufacturer. Their main processing machines, including Plastic Waste Recycling Machine (Spaghetti Type with Side-feeding), PP Woven Mat Machinery, Plastic Waste Recycling Machinery, PP / PE Monofilament Rope Machinery, PP Fiber Rope (Polytwine) Making Plant, PP Woven Sack Machinery, PE Tarpaulin Making Equipment and Fan Guard Machinery, which are sold worldwide with solid reputation.

TON KEY INDUSTRIAL CO., LTD. is a Specialist manufacturer / exporter of plastic processing machinery. Main Product: Plastic Recycling Machine, PP Rope Making Machine, PP Heavy Duty Packing Tape Making Machine, Needle Loom...etc. TON KEY's industrial plastic processing machines are built with alloy steel screw and T-Die for long-lasting efficiency and duration. They are also lightweight, water resistant, high strength and easy to operate.

TON KEY has been offering customers high-quality plastic processing machines and production lines, both with advanced technology and 30 years of experience, TON KEY ensures each customer's demands are met.

.jpg?v=18e84d29)

.jpg?v=950e457f)