.jpg?v=51fcaf8f)

PP Woven Mat Machinery

PP Woven Mat Making Machinery

PP Woven Mat is generally used for praying, Interior decoration (floor mat, wall decoration, table mat), and leisure (beach mat, outdoor blanket) etc.

Since 2016, the loom has been greatly upgraded, and its stability, reliability, and productivity are well recognized in the market.

Now, 9 models are available for different mat width requirement: 90 cm, 120 cm, 150 cm, 180 cm, 200 cm, 220 cm, 250 cm, 270 cm and 300 cm.

Just let us know what kind of product you would like to produce, mat size (width x length) and ideal output (pc/hr. or pc/day), so that we can provide complete proposal and suitable solution of all machines and accessories required for you.

We are willing to share our experience for helping you to complete your production line and production efficiency increasing.

Please feel free to contact us if you need any further information about PP Woven Mat Production Line.

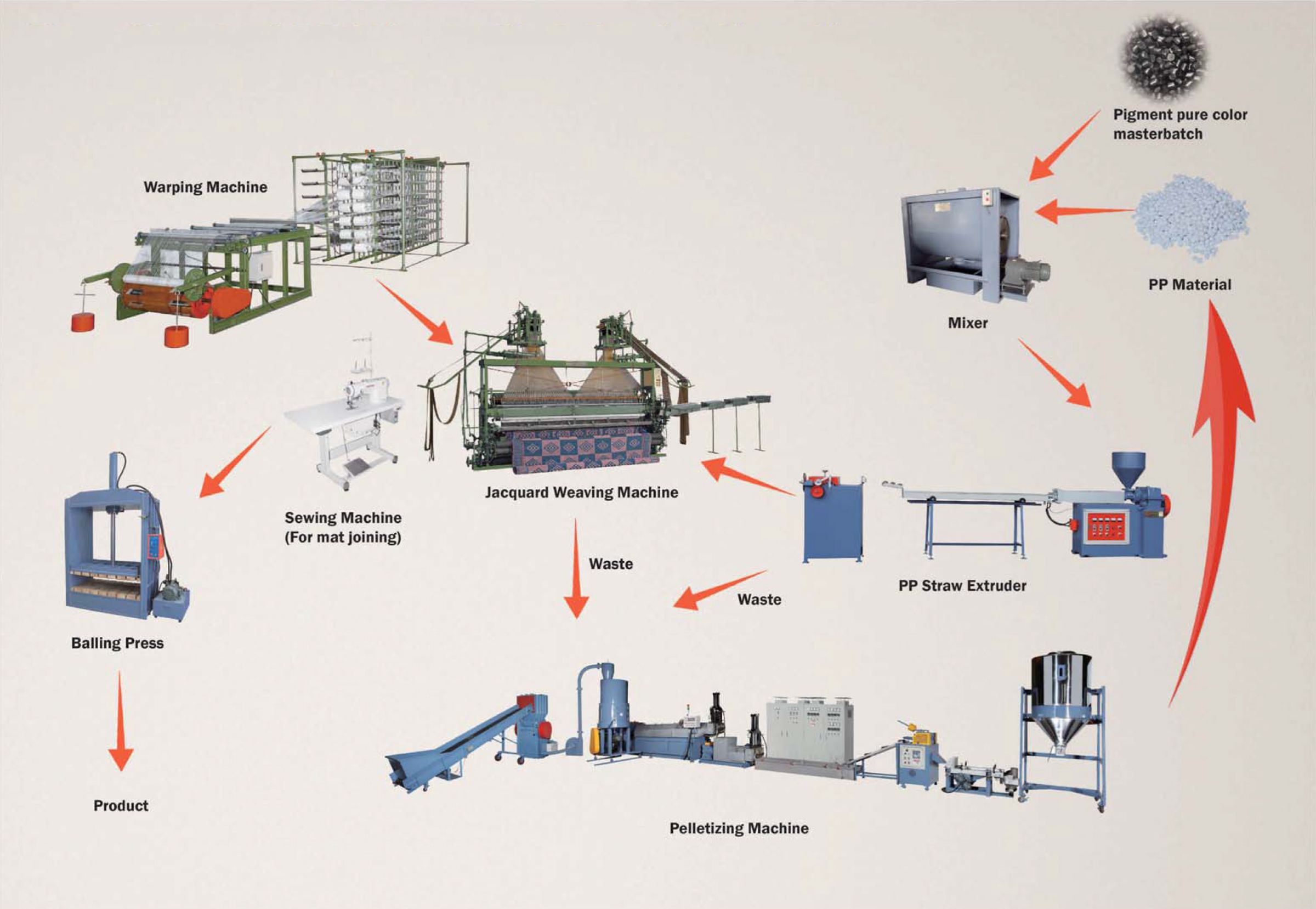

Flow Chart / PP Woven Mat Machinery

Auto Jacquard Weaving Machine

V-TY-36AL, V-TY-48AL, V-TY-60AL, V-TY-72AL, V-TY-78AL, V-TY-86AL, V-TY-98AL, V-TY-106AL, V-TY-120AL

New feature of weaving machine: New-Type Imichi (Weft Straw Guider), Auto Control Panel, Counting...

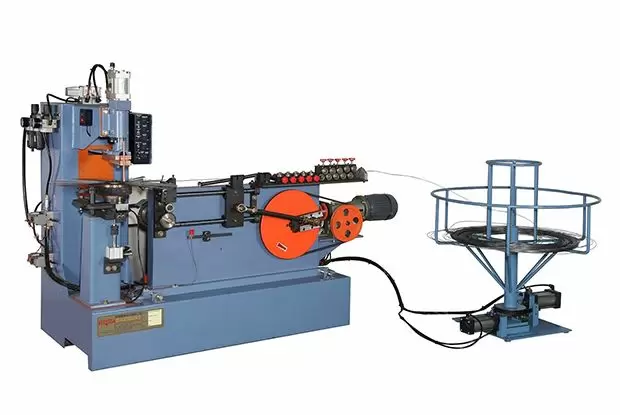

DetailsPP Straw Extruding Machine

V-TY-35M, V-TY-50M, V-TY-65M

The PP Straw Extruding Machine can work with 100% recycled PP. We supervise the quality and processing...

DetailsWarping Machine

V-TY-48Y

Warping Machine is warping yarn (polyester, multifilament yarn) setting machine in beam for producing...

DetailsPP Mat Sewing Machine

V-TY-5N

Sewing Machine is for joining 2 or 3 pcs of mats together, including sewing head, stand, working...

DetailsWater Cooling Tower and Pump

LBC-3 ~1500

Water Cooling Tower and Pump is for water cooling for Extruder.

DetailsMat Heat Cutting Machine (Manual Type)

This Cutting Machine is good for PP Mat and PP Rattan-Like Mat.

DetailsPP Mat Design Card

Lots of designs are available upon request. Customized designs are welcome (please specify...

DetailsPP Woven Mat Machinery - PP Woven Mat Making Machinery | Plastic Processing Machines Manufacturer | TON KEY

Located in Taiwan since 1987, TON KEY INDUSTRIAL CO., LTD. has been a plastic processing machinery manufacturer. Their main processing machines, including PP Woven Mat Machinery, PP Woven Mat Machinery, Plastic Waste Recycling Machinery, PP / PE Monofilament Rope Machinery, PP Fiber Rope (Polytwine) Making Plant, PP Woven Sack Machinery, PE Tarpaulin Making Equipment and Fan Guard Machinery, which are sold worldwide with solid reputation.

TON KEY INDUSTRIAL CO., LTD. is a Specialist manufacturer / exporter of plastic processing machinery. Main Product: Plastic Recycling Machine, PP Rope Making Machine, PP Heavy Duty Packing Tape Making Machine, Needle Loom...etc. TON KEY's industrial plastic processing machines are built with alloy steel screw and T-Die for long-lasting efficiency and duration. They are also lightweight, water resistant, high strength and easy to operate.

TON KEY has been offering customers high-quality plastic processing machines and production lines, both with advanced technology and 30 years of experience, TON KEY ensures each customer's demands are met.

.jpg?v=7843c7c4)

.jpg?v=88060b60)

.jpg?v=9696d2c6)